Building a Hot Tub Platform Your Complete Guide

Building a hot tub platform is a rewarding project, transforming your backyard oasis into a luxurious retreat. This comprehensive guide walks you through every step, from initial planning to final touches, ensuring your platform is both beautiful and functional. We’ll cover various platform types, materials, design considerations, and crucial aspects like drainage and maintenance.

From choosing the right location and platform material to constructing a stable and level foundation, we’ll provide practical advice and detailed instructions. This guide also tackles customization options, integrating landscaping, lighting, and safety features, making your hot tub platform truly unique.

Introduction to Hot Tub Platforms

A hot tub platform is a structural foundation designed to support a hot tub, ensuring stability and safety. It provides a level and stable surface for the hot tub, protecting the surrounding landscaping and preventing damage to the underlying soil. Properly constructed platforms also enhance the aesthetic appeal of the hot tub area.

Hot tub platforms are crucial for the safe and long-lasting enjoyment of your hot tub. They prevent uneven settling, which can lead to premature damage to the hot tub itself. Careful consideration of materials, design, and support systems ensures a durable and attractive addition to any backyard.

Types of Hot Tub Platforms

Different materials offer various advantages for hot tub platforms. Understanding these options is essential for selecting the right solution for your needs.

- Concrete platforms are a classic choice, known for their strength and durability. They can be customized to fit various aesthetic preferences, and with proper reinforcement, they can withstand significant weight.

- Composite platforms offer a blend of aesthetic appeal and durability. These platforms are often made from a combination of materials like fiberglass and resins, providing a strong, weather-resistant surface.

- Steel platforms are a more budget-friendly option, especially when fabricated with appropriate reinforcements. They provide a sturdy base, though they might not offer the same aesthetic flexibility as concrete or composite platforms.

Materials Used in Hot Tub Platform Construction

The choice of materials directly impacts the platform’s lifespan and performance.

- Concrete, a common material, offers excellent compressive strength. Reinforcement with steel rebar is crucial to resist cracking and ensure structural integrity. Different concrete mixes offer varying degrees of durability, depending on the intended use and environmental conditions.

- Composite materials often combine fiberglass and resins, resulting in a strong and weather-resistant platform. These materials are generally low-maintenance and can be molded into various shapes, enhancing aesthetic flexibility.

- Steel, often used in framing, provides a solid base. Proper galvanization or other protective coatings are vital to prevent rust and corrosion over time. The thickness and type of steel will impact the platform’s weight-bearing capacity and durability.

Design Considerations for Hot Tub Platforms

Careful design is critical to ensure the platform’s longevity and the safety of the hot tub.

- The platform’s size should be sufficient to accommodate the hot tub and any surrounding amenities like seating or lighting. Measurements should include the hot tub’s dimensions, as well as any additional space needed for ease of access and maintenance.

- The slope of the platform is crucial for proper drainage. A slight incline, typically around 1/4 inch per foot, directs water away from the hot tub, preventing water accumulation and potential damage.

- Consider the surrounding landscaping. The platform should integrate seamlessly with the existing landscape, enhancing the overall aesthetic appeal. The design should also consider the ease of access and maintenance for the hot tub.

Platform Support and Drainage

Robust support and efficient drainage are paramount for a long-lasting hot tub platform.

- Proper support involves considering the soil conditions and the weight of the hot tub. A platform supported by a foundation system designed to distribute weight evenly ensures stability and prevents settling. The foundation should be reinforced to account for the potential expansion or contraction of the ground.

- Drainage systems are essential to prevent water from pooling around the hot tub. Proper grading and the use of drainage pipes or sumps ensure that water is directed away from the platform and hot tub, minimizing the risk of water damage and maintaining the platform’s structural integrity. The drainage system should be designed to accommodate potential precipitation and handle water flow effectively.

Planning and Design

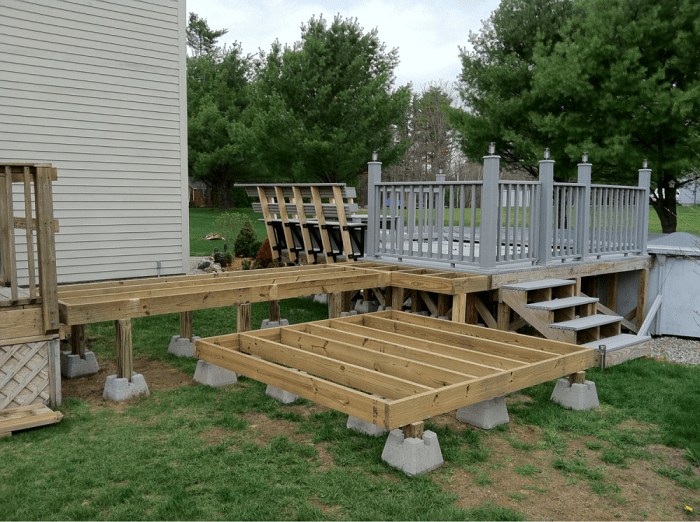

Source: byrossi.com

A well-planned hot tub platform is crucial for both the longevity of the structure and the enjoyment of your hot tub. Careful consideration of location, design, and materials ensures a safe, aesthetically pleasing, and functional addition to your outdoor space. This section will guide you through the essential steps for a successful project.

Thorough planning is key to a successful hot tub platform. This includes selecting the ideal location, determining the appropriate size and design, and choosing the most suitable materials. This approach not only maximizes the enjoyment of your hot tub but also ensures the platform’s structural integrity and longevity.

Platform Location Selection

Choosing the right location for your hot tub platform is paramount. Factors like accessibility, safety, and aesthetics play a vital role.

- Accessibility: Ensure the platform is easily accessible for entry and exit. Consider the slope of the ground and any potential obstacles. A gentle incline or flat terrain is preferred.

- Safety: The location should be free from potential hazards such as falling branches, uneven ground, or proximity to dangerous areas. Clear sightlines for potential dangers should be maintained. A secure location away from heavy traffic is also crucial.

- Aesthetics: Select a location that complements the existing landscape and architectural style of your home. Consider the view from the platform and how it integrates with the surrounding elements.

- Utilities: Plan for proximity to necessary utilities, such as electrical outlets for the hot tub and any lighting needed. Ensure that plumbing lines can be easily connected.

- Drainage: The area should have proper drainage to prevent water accumulation and potential damage to the platform and surrounding landscaping. A well-drained location is essential for the long-term stability of the structure.

Platform Layout Design

A well-defined layout is essential for a functional and visually appealing platform.

- Standard Hot Tub Layout: A standard hot tub platform typically includes a level surface area that comfortably accommodates the hot tub, a surrounding area for easy access and potential seating, and space for the electrical and plumbing connections. This layout prioritizes both functionality and aesthetics.

Considerations for Varying Hot Tub Sizes and Shapes

The platform’s dimensions must accommodate the hot tub’s size and shape.

- Large Hot Tubs: Larger hot tubs require a larger platform to provide adequate space for users and safety. The platform should have sufficient area around the tub to allow for easy movement and egress. A larger hot tub will require a proportionally larger platform.

- Unusual Shapes: Non-rectangular hot tubs require a custom platform design to ensure proper support and stability. The platform’s shape must conform to the hot tub’s unique design.

Platform Material Comparison

Choosing the right material is crucial for the platform’s durability and aesthetic appeal.

| Material | Pros | Cons |

|---|---|---|

| Concrete | Durable, strong, relatively inexpensive, long-lasting, and weather-resistant | Heavy, requires substantial labor and time for installation, and can be prone to cracking if not properly reinforced. |

| Pressure-treated Lumber | Relatively affordable, relatively quick to install, can be customized, and aesthetically versatile. | Susceptible to rot and decay, susceptible to insect damage, may require regular maintenance, and may need periodic replacement.t |

| Composite Decking | Low maintenance, resistant to rot, insects, and decay, and durable | More expensive than pressure-treated lumber, it may not be as strong as concrete in high-traffic areas |

Construction Techniques

Building a sturdy and reliable hot tub platform requires careful consideration of materials, techniques, and safety protocols. A well-constructed platform not only ensures the longevity of your hot tub but also contributes to the overall aesthetic appeal of your backyard. Different materials offer varying advantages, influencing the construction process and the final product.

Concrete, composite, and steel platforms each present unique characteristics and construction methodologies. The choice of material directly impacts the cost, durability, and installation complexity. Thorough planning and execution are crucial to achieving a stable, level, and waterproof platform.

Concrete Hot Tub Platforms

Concrete platforms offer a robust and long-lasting solution. Their strength and ability to withstand significant weight make them ideal for larger hot tubs. However, concrete requires careful pouring and curing to achieve optimal results.

- Formwork Setup: Precise formwork is essential to create the desired shape and dimensions of the platform. Carefully measure and cut the formwork pieces, ensuring they are properly aligned to avoid uneven surfaces.

- Reinforcement Installation: Reinforcing the concrete with steel bars (rebar) significantly increases its strength and prevents cracking. A proper rebar layout is critical for supporting the weight of the hot tub and ensuring structural integrity.

- Concrete Pouring and Curing: A consistent concrete mix is vital for optimal strength. Pouring the concrete evenly into the formwork, ensuring no voids or pockets, is critical. Proper curing, which involves maintaining moisture content, is essential to allow the concrete to fully harden and achieve its designed strength.

- Finishing and Leveling: After the concrete has cured, the surface needs to be smoothed and leveled. This is often achieved using a concrete float or trowel to ensure a smooth and level surface for the hot tub installation.

Composite Hot Tub Platforms

Composite platforms are gaining popularity due to their durability and aesthetic appeal. They are often easier to install than concrete and are available in a wide array of colors and styles.

- Base Preparation: Ensure a level and stable base for the composite platform. This typically involves grading the ground, adding a layer of compacted gravel, and ensuring proper drainage.

- Frame Assembly: The composite platform’s frame is often prefabricated, making assembly straightforward. Carefully follow the manufacturer’s instructions for precise alignment and connection of the frame components.

- Platform Installation: Carefully position the composite platform on the prepared base. Precise alignment is crucial to ensure proper leveling and stability.

- Finishing Touches: Composite platforms often require little finishing, as they typically come in a pre-finished state. However, some platforms may require sealant or caulking for enhanced water resistance.

Steel Hot Tub Platforms

Steel platforms provide a strong and versatile option, particularly for elevated or sloped installations.

- Frame Construction: The steel frame should be designed to accommodate the hot tub’s weight and dimensions. Welding or bolting are common methods for connecting steel members. Reinforcement may be necessary depending on the hot tub size and the site conditions.

- Support Installation: Properly secure the steel frame to the ground using appropriate anchors and footings. This step is critical for the platform’s stability.

- Platform Finishing: Steel platforms are typically painted or coated to prevent rust and enhance aesthetics. Proper preparation of the steel surface before coating is crucial for a long-lasting finish.

- Leveling and Stability: Precise leveling is crucial. Leveling tools and adjustments are essential for ensuring the platform supports the hot tub evenly.

Platform Stability and Levelness

Ensuring the platform’s stability and levelness is paramount to the hot tub’s longevity and user experience.

- Foundation Assessment: The condition of the underlying soil is a critical factor. Soil testing may be necessary to determine the required support structure to accommodate the weight of the hot tub and platform.

- Leveling Procedures: Employing leveling tools, like a laser level, is essential for achieving a perfectly level platform. Adjustments to the supporting structure may be required to ensure the platform is perfectly level.

Waterproofing and Sealing

Protecting the platform from water damage is essential for preventing long-term deterioration.

- Sealing Materials: Appropriate sealants and waterproofing membranes should be used to protect the platform from moisture penetration. These should be chosen based on the material of the platform.

- Proper Application: Sealants and membranes should be applied according to the manufacturer’s instructions for optimal results. Overlapping and sealing seams are crucial for complete protection.

Materials and Tools

Building a hot tub platform requires careful consideration of the materials and tools involved. Proper selection ensures a sturdy, aesthetically pleasing, and safe structure. This section details the essential components and their associated costs.

Essential Materials, Building a Hot Tub Platform

Choosing the right materials is crucial for the longevity and stability of the platform. A well-constructed platform should withstand the weight of the hot tub and potential environmental stresses, such as weather and ground movement. The primary materials for a hot tub platform generally include concrete, lumber, and specialized deck materials.

- Concrete: Forms the foundation and base for the platform, providing structural support and durability. Different types of concrete (e.g., pre-mixed, ready-mix) will affect the cost and workability. A suitable concrete mix ensures proper strength and waterproofing.

- Lumber: Used for framing, support beams, and decking. Select lumber grades appropriate for the intended load. Pressure-treated lumber is often recommended for its resistance to rot and decay, significantly increasing the lifespan of the platform.

- Deck Materials: Materials such as composite decking, treated wood, or even pavers provide the finished surface for the platform. These materials come in various colors and styles to match the aesthetics of the surrounding landscape.

- Fasteners: Screws, bolts, and other fasteners are critical for securely joining the various components. Appropriate fasteners for the materials used are essential for long-term structural integrity.

Tools Required

A comprehensive set of tools is necessary for efficient and safe construction. These tools cover tasks from excavation to finishing touches.

- Excavation Tools: Shovels, backhoes, and other tools for digging the foundation are necessary. The depth and dimensions of the excavation will depend on the specific project requirements.

- Power Tools: Circular saws, drills, and concrete mixers are essential for cutting, assembling, and mixing materials. Choosing the appropriate power tools based on the materials and tasks is important for productivity and efficiency.

- Hand Tools: Hammers, levels, measuring tapes, and other hand tools are crucial for precision and detailed work. Having the right hand tools for the job streamlines the construction process.

- Safety Equipment: Safety glasses, gloves, and hard hats are crucial for preventing injuries during construction. Compliance with safety regulations and proper use of equipment is essential.

Material Cost Comparison

The cost of materials can vary considerably depending on the type, quality, and quantity required. For instance, pre-mixed concrete is typically more expensive than ready-mix concrete. Similarly, high-end composite decking will be more costly than pressure-treated lumber.

| Material | Approximate Cost Range (per unit/sq ft) | Notes |

|---|---|---|

| Pre-mixed Concrete | $50-$80/cubic yard | Higher initial cost, but often more convenient |

| Ready-mix Concrete | $40-$70/cubic yard | Lower cost, but requires scheduling and delivery |

| Pressure-treated Lumber | $5-$15/board foot | Cost varies based on species and grade |

| Composite Decking | $10-$25/sq ft | Higher cost but more durable and low-maintenance |

Labor Cost Estimate

Estimating labor costs depends on factors like the platform’s size, complexity, and local labor rates. A small, simple platform might cost around $2,000-$5,000 for labor, while a larger, more elaborate platform could cost significantly more. Factors such as permits, inspections, and additional site conditions will affect the total labor costs.

Labor costs can be estimated based on project size, complexity, and local labor rates. An experienced contractor can provide more precise estimations.

Safety Precautions

Safety should be paramount during construction. Adherence to safety precautions is essential to prevent accidents and injuries.

- Wear appropriate safety gear. This includes safety glasses, gloves, and hard hats. Using proper safety equipment is crucial to prevent injuries.

- Use tools correctly and follow the manufacturer’s instructions. Incorrect use can lead to accidents and injuries. Proper tool handling is critical.

- Ensure proper ventilation when working with concrete. Exposure to concrete dust can be harmful. Following safety guidelines for concrete work is crucial.

- Inspect all materials and tools before use. This helps prevent accidents and injuries. Thorough inspections help maintain safety standards.

Maintenance and Safety

Proper maintenance and safety precautions are crucial for ensuring the longevity and safe use of a hot tub platform. Neglecting these aspects can lead to structural issues, potential hazards, and even injuries. This section includes Artikels’ essential procedures and considerations to maintain a safe and durable platform.

Maintenance Procedures

Regular maintenance is key to preventing issues and extending the lifespan of the platform. A well-maintained platform will resist the elements and remain stable over time. Addressing potential problems early minimizes costly repairs and ensures continued enjoyment.

Consistent inspection and cleaning are critical components of platform maintenance. This involves checking for any signs of damage, such as cracks, splintering, or rust. Regular cleaning prevents the accumulation of debris and moisture, which can accelerate deterioration. Thorough cleaning also contributes to preventing the growth of mold and mildew, maintaining a sanitary environment around the hot tub.

- Visual Inspection: Regular visual inspections should be conducted to identify any signs of deterioration, such as cracks, warping, or rust. Inspecting for any evidence of water damage, like discoloration or swelling, is equally important.

- Cleaning: The platform should be cleaned regularly to remove dirt, debris, and accumulated moisture. This will help prevent the growth of mold and mildew and will also maintain the aesthetic appeal of the platform.

- Sealant Maintenance: Inspect and reseal any cracks or gaps in the platform’s sealant or caulking as needed. This is crucial to prevent water damage, especially in areas prone to moisture, like corners and joints.

Safety Hazards

Potential safety hazards associated with hot tub platforms encompass various aspects. Ensuring stability and preventing slips and falls are paramount. Properly secured handrails and non-slip surfaces are essential to prevent accidents.

Water damage, especially if not addressed promptly, can lead to structural instability and potential collapse. Additionally, uneven settling of the platform can compromise the stability of the hot tub itself, posing a significant safety concern.

- Unstable Support Structures: Deteriorating support structures can lead to a collapse of the platform or hot tub. A sudden shift in the platform could cause injury to users.

- Inadequate Drainage: Poor drainage around the platform can lead to water pooling, which can cause slipping hazards. This is especially important in areas prone to rain or snow.

- Slippery Surfaces: Improperly maintained surfaces, such as those with accumulated debris or moisture, can create dangerous slip-and-fall hazards.

Preventive Maintenance

Implementing preventive maintenance measures significantly extends the lifespan of a hot tub platform. These measures involve proactive steps to mitigate potential issues. Regular maintenance tasks and prompt repairs are essential for long-term durability.

Addressing potential issues like water damage early is crucial to prevent further deterioration. Regularly inspecting for signs of water damage and prompt repairs can prevent significant structural damage and potential safety hazards.

- Regular Inspections: Periodic visual inspections for any signs of damage, deterioration, or settling are vital to identify and address issues before they escalate.

- Sealant Applications: Resealing cracks and gaps in the sealant is crucial to prevent water penetration and protect the platform’s structural integrity.

- Proper Drainage: Ensure proper drainage around the platform to prevent water accumulation, which can cause structural damage and create slipping hazards.

Addressing Water Damage and Settling

Addressing issues like water damage or settling promptly is critical to maintaining the platform’s structural integrity and safety. Water damage can lead to weakening of the support structure, causing significant issues. Similarly, settling can cause uneven support, impacting the hot tub’s stability.

Early intervention is key to minimizing the impact of these issues. Identifying and rectifying problems quickly will avoid significant structural damage and costly repairs down the road.

- Water Damage Repair: If water damage is detected, promptly address the source of the leak and repair the affected areas. This often involves replacing damaged components or applying waterproofing materials to affected areas.

- Settling Adjustments: If settling is observed, consult with a professional to determine the cause and implement appropriate adjustments to restore the platform’s level and stability.

Maintenance Task Frequency

The following table lists common maintenance tasks and their recommended frequency.

| Maintenance Task | Frequency |

|---|---|

| Visual Inspection | Weekly |

| Cleaning | Monthly |

| Sealant Inspection/Repairs | Quarterly |

| Drainage System Check | Biannually |

Troubleshooting and Common Problems: Building A Hot Tub Platform

Constructing a hot tub platform involves various steps, and unforeseen issues can arise. Careful planning, meticulous execution, and a proactive approach to troubleshooting are crucial for a successful project. Recognizing potential problems and having solutions readily available minimizes costly delays and ensures a stable, functional platform.

Common issues during hot tub platform construction include instability, drainage problems, water leaks, and uneven surfaces. Addressing these issues promptly and correctly prevents further damage and ensures the platform meets safety standards and the needs of the hot tub. Understanding the root causes of these issues and employing effective repair strategies are vital for maintaining the platform’s integrity and longevity.

Identifying Platform Instability

Platform instability is a common concern. Factors such as inadequate foundation preparation, improper anchoring, or insufficient support beams can lead to instability. Visual inspection for settling, uneven support points, or cracks in the concrete or framing members is essential. A thorough assessment of the entire platform structure, including the foundation, is critical to identify the source of the problem. Using a level or straightedge can reveal unevenness in the platform’s surface, while checking the anchoring points ensures they are securely fastened.

Resolving Drainage Problems

Proper drainage is essential for preventing water accumulation around the platform. Clogged or insufficient drainage systems can lead to water pooling, which can compromise the platform’s stability and structural integrity. Adequate grading around the platform ensures proper water runoff. Inspecting the drainage system for blockages and ensuring correct grading are crucial. If necessary, additional drainage channels or French drains might be required.

Addressing Water Leakage

Water leakage can occur due to cracks in the concrete, gaps in the sealant around the hot tub, or faulty plumbing connections. Identifying the source of the leakage is crucial for effective repair. Carefully inspect the platform for any cracks, gaps, or signs of water intrusion. Applying a waterproof sealant to the affected areas can help prevent future leaks. Replacing faulty components, like faulty plumbing connections, will also help prevent water leakage.

Repairing Common Platform Damages

Minor damages to the platform, such as cracks or minor structural damage, can be repaired using appropriate materials and techniques. Identifying the extent of the damage and using suitable repair materials is key. For cracks, epoxy or concrete patching materials can be used. For structural damage, reinforcing the affected areas with additional supports or bracing is essential. A step-by-step guide for repairing common platform damages is provided below.

- Assess the Damage: Carefully examine the platform for any cracks, damage, or unevenness.

- Gather Materials: Collect the necessary materials for repair, such as epoxy, concrete patching material, or reinforcing materials, depending on the extent of the damage.

- Prepare the Area: Clean the affected area thoroughly to remove debris and loose materials.

- Apply Repair Material: Follow the manufacturer’s instructions for applying the chosen repair material. Ensure proper curing time.

- Reinforce (if necessary): If structural damage is present, reinforce the area with additional supports or bracing to restore stability.

- Inspect and Verify: After the repair, inspect the platform to ensure it is stable and structurally sound.

Troubleshooting Table

| Problem | Possible Causes | Troubleshooting Steps |

|---|---|---|

| Platform Instability | Inadequate foundation, improper anchoring, and insufficient support beams | Inspect for settling, uneven supports, and cracks. Secure anchoring points. Add support beams if necessary. |

| Drainage Problems | Clogged drains, insufficient grading | Clear clogs, ensure proper grading around the platform. Consider additional drainage channels if needed. |

| Water Leakage | Cracks in concrete, gaps in sealant, and faulty plumbing | Inspect for cracks, gaps, or leaks. Seal cracks with waterproof sealant. Repair or replace faulty plumbing. |

| Uneven Surfaces | Improper leveling of the foundation and settling of the platform | Level the platform using shims or other leveling materials. Check the foundation for settling and take corrective action. |

Illustrative Examples

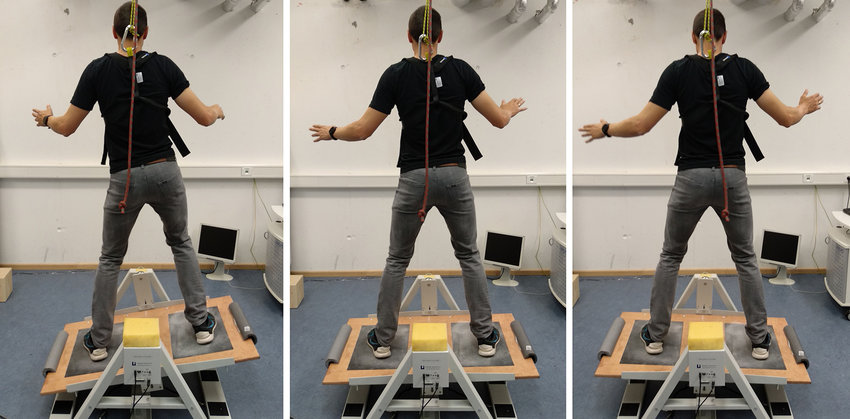

Source: wikihow.com

Building a hot tub platform requires careful consideration of design, materials, and specific site conditions. These examples demonstrate various approaches to platform construction, highlighting different levels of sophistication and budget considerations.

Different factors influence platform design, including the hot tub’s size and weight, the terrain, and local building codes. Careful planning and execution are crucial for a safe and aesthetically pleasing outcome.

High-End Hot Tub Platform Design

This design prioritizes aesthetics and durability, often using premium materials. A high-end platform might feature a custom-designed deck, constructed from composite decking or treated lumber. The platform would be elevated on a reinforced concrete base, incorporating a drainage system that includes a sump pump for efficient water removal. High-end designs often include features like built-in lighting, integrated seating areas, and a surrounding landscape design. Consideration of the surrounding landscaping and architectural style is paramount.

Simple and Cost-Effective Hot Tub Platform Design

A budget-conscious design might use pressure-treated lumber for the platform frame and a poured concrete base. This design often prioritizes functionality over elaborate features. The concrete base provides stability and a level surface for the hot tub, while the pressure-treated lumber is cost-effective and relatively easy to work with. The drainage system would typically consist of a simple slope to a drain. This design could be further enhanced by using readily available, pre-fabricated components.

Platform Design for a Spa with a Hot Tub

A spa with a hot tub necessitates a larger platform design. The platform must accommodate both the spa and hot tub, ensuring sufficient space for access and maintenance. The design should incorporate multiple access points and walkways. This design would likely use reinforced concrete for the base, with a deck constructed from composite decking for durability and ease of maintenance. The drainage system would need to be designed to handle the water from both the spa and the hot tub. Consideration should be given to the aesthetic integration of the spa and hot tub into the platform design.

Platform Design for a Hot Tub Requiring a Unique Drainage Approach

This design addresses unique drainage challenges, such as a sloping site or proximity to a drainage system. If the site slopes heavily, the platform design would need to incorporate a robust drainage system, perhaps including a series of French drains or a more complex sump pump system. This would prevent water from accumulating around the hot tub. Additionally, if the hot tub is located near a drainage system, the design would need to consider proper connection and outflow for water disposal.

Platform Design Incorporating Accessibility Features

This design caters to users with mobility limitations, ensuring safe and convenient access to the hot tub. The platform would incorporate ramps or gentle slopes for easy entry and exit. Handrails or grab bars would be integrated into the design for added support. The platform’s surface would be non-slip and easy to clean, further enhancing safety and usability. This design might incorporate wider walkways, ensuring ample space for wheelchairs and other mobility devices. The platform’s height would be carefully considered to ensure accessibility standards are met.

End of Discussion

This guide has provided a thorough overview of building a hot tub platform, equipping you with the knowledge and insights to confidently embark on your project. We’ve covered everything from foundational planning to advanced customization, ensuring a seamless transition from initial concept to a finished, stunning platform. By following the steps and considering the factors discussed, you’ll not only create a safe and enjoyable hot tub experience but also a beautiful addition to your outdoor space.