Steel Stage Decks A Comprehensive Guide

Steel stage decks are essential for events and performances, providing a stable and safe platform for performers and audiences. They come in various forms, from modular systems to custom-built designs, each suited to specific needs and applications. Understanding the material properties, construction methods, and safety considerations is critical for ensuring the longevity and reliability of these vital structures.

This guide delves into the intricate world of steel stage decks, exploring their design, construction, and safety aspects. From the selection of steel grades to the meticulous assembly procedures, every detail is covered to equip readers with a comprehensive understanding. Safety standards and maintenance protocols are also highlighted to ensure the continued safe use of these structures.

Introduction to Steel Stage Decks

Steel stage decks are specialized platforms constructed from steel, designed to support heavy equipment, performers, and large crowds at events like concerts, theatrical productions, and festivals. Their robust construction and adjustable design make them ideal for diverse applications requiring stability and load-bearing capacity.

These versatile structures are adaptable to various settings and demands. Their strength and durability are crucial for ensuring safety during high-traffic events, while their modularity enables quick assembly and disassembly, minimizing downtime and maximizing efficiency.

Types of Steel Stage Decks

Steel stage decks are available in diverse forms, each catering to specific needs. Modular decks offer pre-fabricated sections that can be easily assembled and reconfigured, allowing for customization of the stage layout. Custom-built decks are tailored to specific project requirements, ensuring precise dimensions and load-bearing capabilities. These are often constructed for unique event designs or use in very specific and complex environments.

Applications of Steel Stage Decks

Steel stage decks are essential components in a wide array of settings. Their use in concerts and music festivals is widespread, supporting performers and equipment. In theatrical productions, they provide a stable platform for elaborate sets and costumes, allowing for intricate stage movements. They also find use in corporate events, trade shows, and other gatherings, enhancing the visual appeal and functionality of the venue.

Safety and Compliance Standards

The construction and use of steel stage decks are governed by stringent safety and compliance standards. These regulations are crucial for ensuring the safety of performers, equipment, and attendees. Adherence to these standards involves careful design, rigorous testing, and adherence to local building codes and industry best practices. This ensures that the platform is suitable for the anticipated loads and environmental conditions. Failure to comply with these standards can result in serious injury or even death.

Comparison of Steel Stage Deck Types

| Type | Load Capacity | Material | Cost |

|---|---|---|---|

| Modular | Generally medium to high, dependent on the specific module and its construction | Typically hot-rolled steel sections, often galvanized or coated for corrosion resistance. | Moderate, often competitive due to pre-fabrication |

| Custom-built | Highly variable, tailored to specific requirements and load expectations | High-strength steel alloys, reinforced structures as needed | Higher, reflecting the design and fabrication costs for customized dimensions and features |

The table above provides a general comparison. Specific load capacities, materials, and costs will vary significantly depending on the design, size, and complexity of the project. For example, a modular deck used for a small event will have a lower load capacity and cost compared to a custom-built deck designed for a large-scale concert featuring heavy equipment and a large crowd.

Material Properties and Design

Stage deck construction necessitates a careful consideration of material properties to ensure safety, longevity, and aesthetic appeal. The choice of steel, its grade, and thickness directly impact the deck’s load-bearing capacity, durability, and overall performance. This section delves into the crucial aspects of steel selection and design for optimal stage deck functionality.

Different steel types exhibit varying characteristics, influencing the stage deck’s performance under diverse conditions. Understanding these differences is vital for appropriate material selection. The load capacity, expected environmental exposure, and aesthetic requirements all play a significant role in choosing the right steel type.

Steel Types for Stage Decks

Various steel grades are suitable for stage deck construction, each with its unique mechanical properties. Mild steel, known for its relatively low cost and good weldability, is a common choice for simpler designs. Stainless steel, with its corrosion resistance, is favored for outdoor applications or areas with high humidity. High-strength steel alloys offer superior strength-to-weight ratios, enabling lighter, yet more robust structures. The selection of steel type directly correlates with the expected operational stresses and the environment in which the stage deck will be situated.

Mechanical Properties of Steels

The mechanical properties of steel significantly impact the stage deck’s ability to withstand loads and stresses. Tensile strength, the maximum stress a material can withstand before fracturing, is critical. Yield strength, the stress at which a material begins to deform permanently, dictates the deck’s resistance to permanent deformation under load. Other important properties include elongation, which indicates the material’s ductility, and impact resistance, which assesses its ability to withstand sudden impacts. Proper consideration of these properties ensures a robust and safe stage deck.

Material Selection Criteria

The selection of steel for a stage deck should be meticulously guided by the intended use. For instance, a stage deck subjected to high pedestrian traffic will require a different material selection compared to a deck supporting heavy equipment or stage machinery. Consideration should be given to the expected dynamic loads, such as the weight of performers, equipment, and audience members, as well as static loads from scenery or set pieces. Understanding these load types is essential for determining the necessary tensile and yield strengths.

Determining Optimal Steel Thickness

Determining the optimal thickness of steel for a given load capacity involves a careful analysis of the anticipated stresses. Engineering calculations, considering factors such as the load distribution, support points, and the material’s properties (tensile and yield strengths), are fundamental to achieving an accurate estimation. These calculations typically utilize established engineering formulas and software tools. The result provides a thickness that balances strength and cost-effectiveness.

Impact of Steel Grades on Longevity and Resilience

Different steel grades exhibit varying degrees of resistance to corrosion, fatigue, and impact damage. Mild steel, while cost-effective, may be susceptible to corrosion in outdoor environments. Stainless steel, on the other hand, offers excellent corrosion resistance, making it ideal for long-term use in humid or salty environments. High-strength steel alloys often exhibit enhanced fatigue resistance, which is important for stage decks subjected to repeated loading and unloading. This resilience translates into a longer lifespan for the stage deck.

Steel Properties Table

| Steel Type | Tensile Strength (MPa) | Yield Strength (MPa) | Weight (kg/m3) |

|---|---|---|---|

| Mild Steel | ~350 | ~200 | ~7850 |

| Stainless Steel (304) | ~520 | ~280 | ~8000 |

| High-Strength Steel (e.g., A514) | ~690 | ~500 | ~7850 |

This table provides a general overview of the properties of common steel types suitable for stage decks. Specific values may vary based on the particular steel grade and manufacturing process. Consult relevant engineering standards and specifications for precise values in specific applications.

Manufacturing and Construction Processes

Steel stage decks, crucial for live events and performances, require meticulous planning and execution during manufacturing and construction. Proper adherence to these processes ensures the structural integrity, safety, and longevity of the stage. The procedures detailed below cover the key aspects of manufacturing and assembly.

Manufacturing Processes

Steel stage decks undergo several critical manufacturing processes. These include precision cutting of steel components using CNC (Computer Numerical Control) machines. This method ensures accuracy and repeatability, minimizing errors and maximizing efficiency. Welding techniques, typically employing shielded metal arc welding (SMAW) or flux-cored arc welding (FCAW), are paramount for joining the various components. Post-weld finishing, including grinding and smoothing, ensures a professional aesthetic and smooth surface, critical for safety.

Assembly Process

Assembling a steel stage deck follows a systematic approach. Initial steps involve carefully aligning and positioning the pre-cut steel beams, using appropriate jigs and templates for precision. Next, welding these beams together according to the blueprint, with strict adherence to specifications and quality control measures. The welded joints are inspected for defects and irregularities. Once the frame is complete, the decking plates are installed and secured. This final step often involves bolting or riveting the decking to the frame, ensuring a robust and stable platform. All components should be meticulously checked for proper alignment and secure connections.

Quality Control Measures

Rigorous quality control measures are integral to the construction process. These include pre-weld and post-weld inspections. Visual inspections are conducted at each stage, checking for flaws like cracks, warping, and inconsistencies in the welding. Non-destructive testing (NDT) methods, like ultrasonic testing (UT) or radiographic testing (RT), might be employed to detect internal defects that visual inspection cannot. These measures ensure that the finished product meets safety standards and structural requirements.

Welding Techniques

Proper welding techniques are paramount for safety and structural integrity. Welds must be executed with precision and adherence to established procedures. This involves careful selection of electrode type, amperage, and welding speed, minimizing distortion and ensuring high-quality welds. Welder training and certification are essential to ensure that skilled personnel are performing these critical tasks. Careful consideration of the type of steel being used is critical for selecting the appropriate welding parameters.

Connection Methods

Bolting and welding are the two primary methods used for connecting steel components. Bolting offers flexibility and allows for easier disassembly if required, while welding provides a stronger, permanent connection. The choice of method depends on factors such as the load requirements, the desired level of flexibility, and the need for future modifications. For high-load applications, welding is often the preferred method. In contrast, bolting is more suitable for situations where periodic disassembly or adjustment is necessary.

Material Calculation

Calculating the required amount of steel involves determining the dimensions and weight of the steel deck, considering the anticipated load. Factors such as the weight of equipment, the number of people, and potential external forces should be considered. Engineers employ specialized software and formulas to precisely calculate the steel quantities for the project, avoiding underestimation or overestimation. An example might be a stage deck designed for a 100-person concert, requiring detailed calculations for each component.

Construction Process Summary

| Step | Description | Estimated Time (Days) |

|---|---|---|

| Design and Planning | Blueprint creation, material ordering | 2-3 |

| Cutting and Fabrication | Steel cutting, component preparation | 3-5 |

| Welding | Joint assembly and weld inspection | 4-6 |

| Finishing | Grinding, painting, and surface treatment | 2-3 |

| Assembly | Component joining, decking installation | 3-4 |

| Quality Control | Inspection and testing | 1-2 |

The table above provides a general overview of the construction process and estimated time. Actual timelines can vary based on the complexity of the project, the size of the stage deck, and the availability of resources.

Maintenance and Inspection

Maintaining a steel stage deck ensures its longevity, safety, and operational efficiency. Regular inspections and proper maintenance procedures are crucial for identifying potential issues early, preventing catastrophic failures, and minimizing downtime. This proactive approach is vital to preserving the structural integrity and usability of the stage deck.

Proper maintenance involves a multi-faceted approach encompassing visual inspections, component checks, and adherence to a defined schedule. This meticulous care protects the investment in the stage deck and safeguards performers and audience members.

Inspection Procedures for Damage and Wear

Visual inspections are the cornerstone of proactive maintenance. Thorough visual inspections should cover the entire stage deck surface, including all supports, connections, and fasteners. Inspectors should be trained to recognize signs of damage, such as cracks, corrosion, or deformation. Close examination of welds, bolted connections, and other critical joints is essential. Careful observation for signs of stress concentrations, such as excessive wear or localized corrosion, is also critical.

Maintenance Requirements for Longevity and Safety

Regular cleaning and lubrication are essential maintenance tasks. Cleaning removes debris, dirt, and accumulated moisture that can accelerate corrosion. Proper lubrication of moving parts, if any, reduces friction and wear, ensuring smooth operation and extending the lifespan of the stage deck. Regular tightening of bolts and fasteners is also vital to maintaining structural integrity and preventing loosening or failure.

Importance of Regular Maintenance and Inspections

Regular maintenance and inspections are not merely recommendations; they are essential for ensuring the safety and longevity of the steel stage deck. Ignoring these procedures can lead to unexpected failures, potentially causing injuries or significant damage to the stage deck itself. The cost of repairs after a major failure often outweighs the cost of proactive maintenance. For instance, a small crack left unaddressed can quickly propagate into a significant structural weakness, necessitating costly repairs or even replacement.

Identifying Potential Issues Through Visual Inspections

Visual inspections should focus on identifying potential issues before they become major problems. Inspectors should be trained to recognize signs of corrosion, such as rust or pitting. Deformations, such as bends or warping, can indicate stress concentrations or underlying structural issues. Loose fasteners or missing components should be noted and promptly addressed. Checking for signs of fatigue, such as cracks or hairline fractures, in welds or high-stress areas is critical. Any discrepancy should be documented and reported immediately.

Step-by-Step Guide for Maintaining Steel Stage Decks

- Cleaning: Thoroughly clean the stage deck surface using appropriate cleaning agents and methods to remove debris, dirt, and accumulated moisture. Pay particular attention to joints, welds, and areas prone to the accumulation of debris.

- Lubrication (if applicable): Lubricate moving parts, such as hinges or bearings, using appropriate lubricants to reduce friction and wear. Follow manufacturer recommendations for lubrication type and frequency.

- Component Checks: Inspect all components, including fasteners, welds, and supports, for signs of damage, wear, or looseness. Record any findings and address them promptly.

- Documentation: Maintain detailed records of all inspections, maintenance activities, and any observed issues. This documentation is critical for tracking the stage deck’s condition over time and for planning future maintenance.

Common Maintenance Tasks and Frequency

| Maintenance Task | Frequency |

|---|---|

| Visual Inspection | Weekly |

| Cleaning | Monthly |

| Lubrication (if applicable) | Quarterly |

| Fastener Tightening | Semi-annually |

| Detailed Component Checks | Annually |

| Corrosion Protection Treatment (if required) | As needed/per manufacturer recommendations |

Case Studies and Examples

Source: leadongcdn.com

Steel stage decks, due to their critical role in various events and performances, demand meticulous planning and execution throughout their lifecycle. Successful projects often serve as valuable benchmarks, highlighting best practices and areas for improvement. Understanding the challenges faced in previous projects allows for more informed decision-making in future endeavors.

Thorough analysis of case studies provides invaluable insights into the complexities of designing and constructing these structures. Lessons learned from past projects can be applied to future designs, leading to safer, more efficient, and aesthetically pleasing stage decks. Examining both successful and less successful projects allows for a deeper understanding of the factors influencing the overall outcome.

Successful Steel Stage Deck Projects

Several notable projects have successfully utilized steel stage decks, demonstrating the versatility and robustness of the material. These projects often showcase innovative designs, advanced construction techniques, and meticulous attention to detail. Analyzing these projects provides valuable insight into the successful execution of steel stage deck projects.

- A large-scale outdoor music festival utilized a modular steel stage deck, designed to accommodate diverse performance needs. The modular design allowed for easy reconfiguration and quick setup, minimizing downtime and maximizing the event’s operational efficiency. The deck’s robust construction ensured safety for performers and spectators during high-energy performances.

- A theatre production utilized a custom-designed steel stage deck incorporating intricate lighting and sound integration. The deck’s unique design facilitated seamless movement of equipment and performers, enhancing the overall production quality. Its aesthetic appeal and functionality contributed significantly to the success of the theatrical production.

- A corporate conference showcased a meticulously crafted steel stage deck, designed to blend seamlessly with the venue’s architectural style. The stage deck’s elegant design and durable construction projected a professional image, contributing to the overall success of the event.

Challenges in Steel Stage Deck Design and Construction

Several challenges can arise during the design and construction of steel stage decks. Addressing these challenges proactively is crucial for ensuring project success. Understanding and mitigating these issues leads to a more robust and reliable structure.

- Site constraints: Varied site conditions, including uneven terrain or limited space, can significantly impact the design and construction process. Careful site surveys and detailed design plans are necessary to account for these constraints. Careful planning and innovative solutions are vital for overcoming these challenges.

- Weather conditions: Adverse weather conditions, such as strong winds or heavy rainfall, can disrupt construction schedules and potentially compromise the structural integrity of the deck. Appropriate construction methods and material selection are essential to minimize these risks.

- Budget constraints: Steel stage decks can be complex structures, requiring specialized materials and skilled labor. Budget limitations can impact the design and construction process. Optimizing material selection, minimizing labor costs, and negotiating favorable pricing are crucial for managing these constraints.

Real-World Scenarios

Understanding how proper planning and execution impact the outcomes of steel stage deck projects is critical. These scenarios illustrate the importance of meticulous planning and proactive problem-solving.

- A project experienced significant delays due to unforeseen site conditions. Implementing a comprehensive contingency plan and proactive communication between the design team and construction crew mitigated the impact of the delays, minimizing the project’s overall cost and ensuring the successful completion of the event.

- A project encountered unexpected weather challenges, jeopardizing the timely completion of the deck’s construction. The project team adjusted their construction schedule and utilized appropriate weather-resistant materials, enabling the project to proceed efficiently despite the unexpected conditions.

Image Descriptions

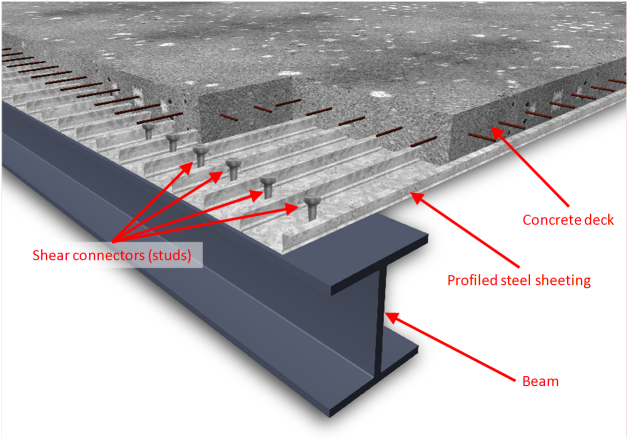

- Image 1: A modern steel stage deck, characterized by its sleek design and modular components. The deck features a series of interconnected panels, offering flexibility for different stage configurations. The image highlights the structural integrity and aesthetic appeal of the modern design. This design is suited for large-scale events where adaptability is paramount.

- Image 2: A traditional steel stage deck, showcasing its robust construction and ability to withstand heavy loads. The image emphasizes the durability and longevity of steel stage decks. This design is suited for venues where the stage needs to accommodate heavy equipment and performers.

- Image 3: A custom-designed steel stage deck integrated into an architectural landscape. The image highlights the versatility of steel stage decks in adapting to various architectural styles. The design’s integration with the surrounding environment demonstrates the aesthetic appeal of steel stage decks.

Lessons Learned, Steel stage deck

Analyzing past projects offers valuable insights for future endeavors. Understanding the challenges and successes allows for informed decision-making and efficient project management.

- Thorough site assessments are crucial for identifying potential challenges and developing appropriate mitigation strategies.

- Collaboration between design, construction, and event management teams is essential for successful project execution.

- Effective communication and clear project documentation are vital for maintaining project timelines and preventing costly delays.

Concluding Remarks

In conclusion, steel stage decks are complex structures demanding careful consideration throughout their lifecycle. From material selection and manufacturing to installation and ongoing maintenance, a multitude of factors influence their performance and safety. By understanding the key principles outlined in this guide, stakeholders can ensure the successful design, construction, and operation of these critical elements in diverse settings.