Aluminum Platform Deck A Comprehensive Guide

Aluminum platform deck construction offers a robust and aesthetically pleasing solution for various applications. From residential patios to commercial walkways, these decks provide durability and low maintenance. This guide explores the design, construction, maintenance, and environmental impact of aluminum platform decks, comparing them to other materials.

Aluminum’s inherent strength and corrosion resistance make it a superior choice for outdoor structures. The design considerations, from safety features to accessibility, are crucial to creating a functional and safe platform. Furthermore, the guide will delve into the cost-effectiveness and environmental responsibility of choosing aluminum for your deck project.

Introduction to Aluminum Platform Decks

Aluminum platform decks offer a modern and durable alternative to traditional wooden or composite decks. Their lightweight yet strong construction, coupled with a wide array of design options, makes them a popular choice for homeowners seeking a long-lasting and aesthetically pleasing outdoor space.

These decks leverage the inherent properties of aluminum, providing resistance to rot, decay, and insect infestation. This resistance to the elements contributes to their longevity and reduced maintenance requirements compared to other materials. Furthermore, their lightweight nature simplifies installation and often allows for customization with varied railing styles and finishes.

Materials Used in Construction

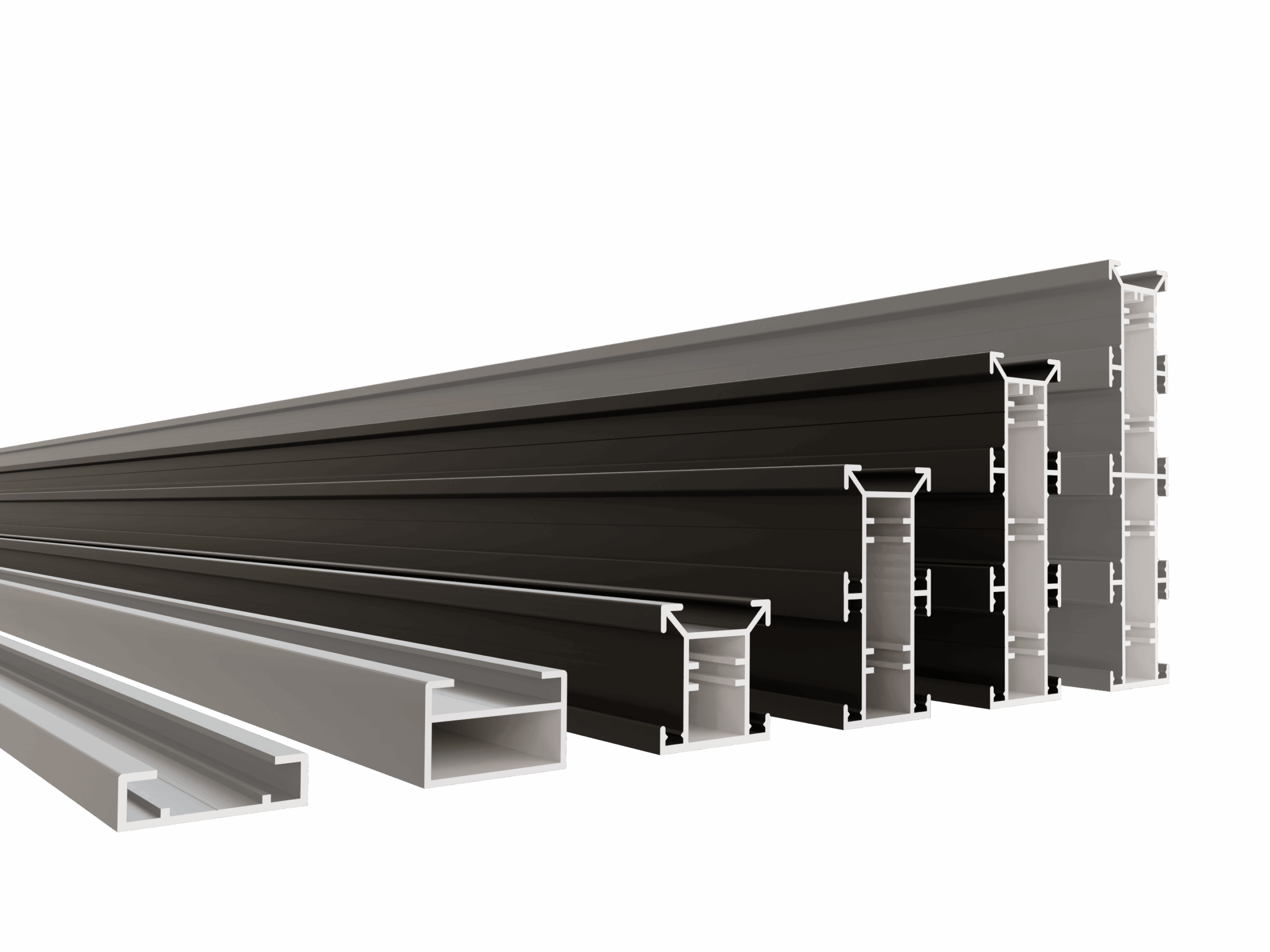

Aluminum platform decks are primarily constructed from extruded aluminum beams and posts. These components are typically joined with high-strength fasteners, such as stainless steel screws and bolts, ensuring structural integrity. Further reinforcing materials, such as concrete footings and specialized decking boards, may be integrated depending on the project’s specifications. The choice of materials often reflects the design intent, load-bearing requirements, and aesthetic preferences.

Key Features and Benefits

Aluminum’s inherent properties contribute to several key features and benefits for platform decks. These include:

- Durability and Longevity: Aluminum’s resistance to corrosion, rot, and decay makes it a remarkably durable material, leading to a long lifespan for the deck. This durability reduces the need for costly repairs and replacements over time, a significant advantage over other materials.

- Low Maintenance: The inherent resistance of aluminum to the elements means significantly less maintenance is required compared to wood or composite decks. This translates to lower costs and less time spent on upkeep.

- Lightweight Construction: Aluminum’s lightweight nature allows for easier installation, reducing labor costs and potential structural support needs, and often permitting more intricate design options.

- Customizability: Aluminum’s adaptability allows for diverse design options in terms of railing styles, finishes, and overall aesthetic. This feature empowers homeowners to create a deck that aligns with their unique style.

Typical Applications

Aluminum platform decks are suitable for various applications, including:

- Residential Homes: Often used as primary outdoor living spaces, connecting homes to patios and gardens.

- Commercial Spaces: Used in hotel balconies, restaurant patios, and other public spaces that require durability and low maintenance.

- Pool Decks: Their resistance to moisture and chemical exposure makes them ideal for poolside areas.

- Hot Tub Decks: Similarly, their resistance to moisture and temperature fluctuations makes them well-suited for areas adjacent to hot tubs.

Aesthetic Considerations

Aluminum platform decks offer a variety of aesthetic options, including a range of finishes and colors. The sleek, modern lines of aluminum are especially appealing, allowing the deck to blend seamlessly with contemporary architectural styles. Finishes can be customized to match the surrounding environment and the home’s exterior.

Design and Construction Considerations

Designing and constructing a safe and durable aluminum platform deck requires careful consideration of various factors. The design process must incorporate not only aesthetic appeal but also critical safety measures to prevent accidents and ensure longevity. This includes choosing appropriate materials, calculating structural loads, and implementing proper connections. Careful attention to detail in the construction phase is equally important for achieving the desired outcome.

The design of an aluminum platform deck must prioritize safety. This involves considering factors like wind load, snow load, and potential impacts. Proper calculations are essential to ensure the deck can withstand these forces and maintain stability. Construction must adhere to local building codes and safety regulations. Using certified materials and employing qualified professionals can help ensure a safe and reliable structure.

Design Process

The design process for an aluminum platform deck involves several key steps. First, a thorough site assessment is crucial to identify the ground conditions, existing structures, and environmental factors like wind patterns. This information informs the structural design calculations. Second, the desired deck size, configuration, and accessibility features are defined. Third, the design incorporates appropriate support systems, connections, and fastening methods. Finally, the design must comply with all relevant building codes and safety regulations.

Safety Factors

Critical safety factors in the design and construction of aluminum platform decks include proper load-bearing capacity, resistance to corrosion, and compliance with safety standards. The deck must be able to support anticipated loads, including the weight of people, equipment, and potential debris. Aluminum’s inherent corrosion resistance is important, but proper coatings and maintenance protocols are necessary for long-term protection. Adhering to local building codes and employing certified professionals is critical to ensuring a safe structure.

Support Systems and Connections

Various support systems and connections are used in aluminum platform decks. These include: posts, beams, and hangers. Aluminum posts are commonly used for vertical support, while beams are used to span horizontal distances. Hangers are used for supporting the deck from beams or other structures. Connections between components should be designed for high strength and durability. Welding and bolting are common methods.

Deck Sizes and Configurations

Aluminum platform decks come in a variety of sizes and configurations. Small decks, often used for patios or balconies, might be only a few square meters in area. Larger decks, suitable for commercial or recreational use, can span several meters and accommodate multiple access points. The configuration may include ramps, stairs, or other features to enhance accessibility. Examples include simple square or rectangular decks, decks with cantilevered extensions, or decks integrated with other structures.

Securing the Deck

Securing the deck to the ground or existing structure involves various methods. For ground-mounted decks, concrete footings or pier foundations are commonly used. For decks attached to existing structures, appropriate anchors and fasteners are employed. The specific method depends on the structure being attached to and the required load capacity. Ensuring proper anchoring is essential to prevent movement and maintain stability.

Accessibility Features

Incorporating accessibility features is crucial for creating inclusive and safe aluminum platform decks. These features include ramps, handrails, and appropriate surface treatments to prevent tripping hazards. Ramps ensure accessibility for individuals with mobility limitations. Handrails provide stability and support. Non-slip surfaces and proper lighting enhance safety for all users.

Fastening Methods Comparison

| Method | Advantages | Disadvantages | Cost |

|---|---|---|---|

| Welding | High strength, permanent connection | Requires specialized equipment and skilled labor, with potential for distortion | Medium to High |

| Bolting | Relatively easy to install, allows for disassembly | May require more hardware, with potential for loosening over time | Medium |

| Fastening with Screws | Fast and relatively inexpensive, easy to install | Lower load capacity compared to welding or bolting, less durable | Low to Medium |

| Adhesive bonding | Aesthetically pleasing, often waterproof | Can be affected by temperature changes, and is time-consuming | Medium |

Maintenance and Durability

Source: timbertech.com

Aluminum platform decks, while known for their strength and aesthetic appeal, require consistent maintenance to retain their quality and longevity. Proper upkeep significantly extends the lifespan of these structures, preventing costly repairs and ensuring a safe and enjoyable outdoor space.

Aluminum’s inherent corrosion resistance contributes substantially to its durability, but environmental factors and exposure can still impact its performance. Understanding the long-term maintenance requirements and the factors affecting lifespan is crucial for maximizing the return on investment and minimizing potential issues.

Long-Term Maintenance Requirements

Regular cleaning and inspection are essential for maintaining the pristine appearance and structural integrity of aluminum platform decks. Routine maintenance helps to prevent the buildup of dirt, grime, and algae, which can contribute to surface degradation. This proactive approach will also allow for prompt identification of any potential damage or wear and tear, enabling timely repairs and avoiding more significant issues.

Factors Affecting Lifespan

Several factors can influence the longevity of aluminum platform decks. Environmental conditions play a significant role, with harsh weather, including prolonged exposure to sunlight, rain, and strong winds, potentially accelerating deterioration. The quality of the aluminum itself and the manufacturing processes used during construction will also impact the deck’s lifespan. Lastly, the application of protective coatings and the quality of installation significantly affect the overall durability.

Common Maintenance Procedures

Regular cleaning is a critical component of maintaining the aesthetic and structural integrity of aluminum platform decks. This can involve pressure washing, using mild detergents, and removing any debris or buildup. Periodic inspections are vital for detecting early signs of damage or corrosion, such as loose fasteners, warped boards, or signs of discoloration. Addressing these issues promptly will prevent minor problems from escalating into major structural concerns. Professional inspections and maintenance are highly recommended at least once a year, especially for decks in harsh environments.

- Pressure Washing: A high-pressure washer can effectively remove dirt, grime, and other debris from the deck surface. Ensure to use a low-pressure setting to avoid damaging the aluminum or any protective coatings. Regular pressure washing can prevent the accumulation of organic matter that can contribute to corrosion.

- Cleaning Solutions: Use mild detergents or specialized aluminum cleaners to clean the deck. Avoid harsh chemicals or abrasive materials, which can scratch or damage the surface. Follow the manufacturer’s instructions for any specific cleaning solutions.

- Inspection for Damage: Regularly inspect the deck for any signs of damage, such as loose fasteners, warped boards, or signs of corrosion. Tighten any loose screws or bolts promptly. Document any significant damage for future reference.

- Protective Coatings: Apply protective coatings as recommended by the manufacturer. This can extend the deck’s lifespan and enhance its resistance to the elements.

Corrosion Resistance of Aluminum, Aluminum platform deck

Aluminum exhibits excellent corrosion resistance due to its natural tendency to form a protective oxide layer. This layer acts as a barrier, preventing further oxidation and protecting the underlying metal from environmental elements. However, factors such as salt spray, chemical exposure, and the presence of moisture can compromise this protective layer, leading to corrosion. This is why proper maintenance and protective coatings are crucial.

Impact of Protective Coatings on Durability

The selection of protective coatings is critical for enhancing the durability of aluminum platform decks. Different coatings offer varying degrees of protection and have unique advantages and disadvantages in terms of cost, longevity, and maintenance.

| Coating Type | Benefits | Drawbacks | Cost |

|---|---|---|---|

| Powder Coating | Excellent durability, chemical resistance, and aesthetic appeal. Available in a wide range of colors and finishes. | It can be more expensive than other options. Requires specialized application equipment. | Medium to High |

| Epoxy Coating | Good chemical resistance, relatively affordable. Provides a durable protective layer. | It may not be as durable as powder coating in extreme environments. May require more frequent reapplication. | Low to Medium |

| Acrylic Coating | Relatively affordable, easy to apply. Good aesthetic appeal. | Lower durability compared to epoxy or powder coating. It may not be suitable for harsh environments. | Low |

| Anodizing | Provides excellent corrosion resistance, enhances surface hardness, and offers a wide range of colors. | More expensive than other coating options. May require specific maintenance procedures. | Medium to High |

Applications and Examples: Aluminum Platform Deck

Source: metaltech.co

Aluminum platform decks offer a versatile and durable solution for a wide range of applications, seamlessly blending aesthetic appeal with practical functionality. Their lightweight yet robust construction, coupled with a range of finishes and customization options, makes them suitable for both residential and commercial settings. This section explores the diverse applications of aluminum platform decks, highlighting design considerations and installation nuances.

Diverse Applications

Aluminum platform decks are increasingly popular for their adaptability. Their use extends beyond traditional residential patios, encompassing various environments. From elevated walkways to poolside platforms, they provide accessible and aesthetically pleasing spaces. Their corrosion resistance and low maintenance requirements make them an excellent choice for marine applications, including docks and piers.

Residential Applications

Residential applications showcase the versatility of aluminum platform decks. Many homeowners choose them for patios, adding a touch of modern elegance to their outdoor living spaces. Examples include decks surrounding swimming pools, creating tranquil and functional areas for relaxation. Elevated walkways connecting different levels of a property or garden areas also benefit from the use of aluminum platform decks. The material’s ease of installation and aesthetic appeal contribute to the overall value and appeal of the property.

Commercial Applications

Commercial applications leverage the durability and longevity of aluminum platform decks. Hotels, resorts, and other hospitality venues often integrate them into their designs, creating attractive spaces for guests. For example, rooftop decks for restaurants and bars offer unique outdoor dining experiences, drawing customers with their sophisticated aesthetic. Similarly, they can be integrated into retail spaces, providing outdoor seating areas for customers, enhancing the overall shopping experience.

Integration with Landscaping and Structures

The integration of aluminum platform decks with landscaping and other structures can dramatically enhance the aesthetic appeal and functionality of a space. Careful consideration of the surrounding environment is crucial. For instance, integrating the deck with a retaining wall can create a seamless transition between different levels of a garden or yard. Decks can also be designed to incorporate features such as built-in seating, planters, or lighting, enhancing the overall design. A deck’s location about trees, shrubs, or other landscaping elements should be thoughtfully considered to maintain harmony.

Key Factors in Choosing an Aluminum Platform Deck

Several factors influence the selection of an aluminum platform deck for a specific application. The primary consideration is the intended use of the deck. For example, a deck intended for heavy use in a commercial setting will require a stronger structural design compared to a residential deck for occasional use. Other important factors include the local climate, the surrounding environment, and the desired aesthetic. Accessibility for individuals with mobility challenges should also be factored into the design.

Residential vs. Commercial Decks

The key difference between residential and commercial aluminum platform decks lies in their design and construction. Residential decks often prioritize aesthetic appeal and homeowner preference, with simpler designs and lighter materials. Commercial decks, however, need to withstand heavier use and traffic, requiring robust construction and potentially more complex designs. Load-bearing capacity, safety features, and durability are critical considerations for commercial applications.

Diagram of a Small Aluminum Platform Deck Installation

+-----------------+

| |

| Frame Structure | <-- Aluminum beams & posts

| |

+-----------------+

|

|

+---------+

| |

| Decking | <-- Aluminum planks/panels

| |

+---------+

|

| Footings (concrete)

|

This simplified diagram illustrates the basic installation process. Aluminum beams and posts form the frame, supported by concrete footings. Aluminum decking planks or panels are secured to the frame, creating the platform.

Pool Area Platform Deck Design Considerations

Designing a platform deck for a pool area requires careful consideration of safety and accessibility. Slip-resistant materials are essential for preventing accidents. The deck’s location should allow for easy access to the pool and other poolside amenities. Compliance with building codes and safety regulations is crucial. Factors like pool size, surrounding landscaping, and the number of anticipated users must be considered in the design process. Careful planning ensures a safe and enjoyable poolside experience.

Cost and Budget Considerations

Aluminum platform decks offer a compelling value proposition, combining attractive aesthetics with impressive durability. However, understanding the cost factors involved is crucial for any homeowner planning a deck project. This section will explore the various cost components, compare aluminum to other materials, and provide a practical cost estimation framework.

Factors Influencing Deck Cost

Several factors significantly impact the overall cost of an aluminum platform deck. Material costs, labor expenses, design complexity, and site-specific conditions all play a role. The size of the deck, the desired features (e.g., railings, stairs, lighting), and the level of customization will also affect the final price. The geographic location of the project can influence labor costs, as well as local regulations and permit fees.

Material Costs

Aluminum, while generally a more expensive material than wood or composite decking, often proves to be more cost-effective in the long run due to its durability and longevity. The cost of aluminum itself, including its fabrication and transportation, can vary. Furthermore, the type of aluminum used and its thickness impact the price. In many cases, the higher initial cost of aluminum is offset by the reduced need for replacement and maintenance over the deck’s lifespan.

Labor Costs

Professional labor costs constitute a significant portion of the total project budget. These costs are directly related to the complexity of the installation, including the size of the deck, the required structural support, and the presence of intricate features. The skill level of the contractors involved also influences the overall labor costs. Factors like the complexity of the design, the location of the work site, and potential permitting delays can all impact labor costs.

Comparison with Other Materials

While aluminum offers a strong value proposition, it’s essential to compare its cost with alternatives. Wood decks, while often less expensive initially, require more frequent maintenance and replacement. Composite decking provides a good balance between cost and durability, but aluminum often offers a comparable or better return on investment in the long term.

Savings through Durability and Longevity

The longevity of aluminum decks translates into substantial potential savings. By avoiding frequent repairs and replacements, homeowners can avoid the recurring costs associated with other materials. The reduced maintenance and the longer lifespan of an aluminum deck contribute to significant long-term savings. For example, a homeowner who avoids costly deck replacements every 10-15 years can save thousands of dollars over the lifetime of the deck.

Estimated Costs for Different Deck Sizes and Features

| Deck Size | Features | Labor Costs | Total Estimated Cost |

|---|---|---|---|

| 10′ x 12′ | Simple platform with basic railing | $3,000 – $4,000 | $6,000 – $8,000 |

| 15′ x 18′ | Platform with stairs and decorative railing | $5,000 – $7,000 | $9,000 – $12,000 |

| 20′ x 25′ | Platform with stairs, pergola, and custom lighting | $8,000 – $12,000 | $15,000 – $20,000 |

Note: These are estimated costs and may vary depending on location, specific materials, and design complexity.

Safety and Regulations

Aluminum platform decks, while offering a robust and aesthetically pleasing solution, necessitate adherence to stringent safety standards and regulations. Proper implementation of these guidelines ensures the safety of users and the structural integrity of the deck. Failure to comply can lead to significant repercussions, including injury and potential legal liabilities.

Safety Standards and Regulations

Aluminum platform decks, like all construction projects, must conform to local, state, and national building codes and safety regulations. These codes Artikel the minimum requirements for materials, design, construction, and maintenance to ensure safe use. Specific standards might address factors such as load-bearing capacity, fall protection, and accessibility for individuals with disabilities. These regulations are crucial for preventing accidents and ensuring the structural integrity of the deck over its lifespan.

Permits and Approvals

Securing necessary permits and approvals is a critical step in the construction process. The specific permits and approvals required vary by jurisdiction. These documents confirm that the construction meets local building codes and safety standards. Applications for permits typically require detailed plans and specifications, including load calculations, material details, and a safety analysis. Obtaining the necessary permits is a prerequisite for the commencement of construction.

Load Capacity and Safety Factors

Load capacity is a critical aspect of platform deck design. The deck must be designed to withstand anticipated loads, including the weight of people, equipment, and potential environmental factors. Designers incorporate safety factors to account for unforeseen circumstances or variations in load distribution. These factors typically exceed the anticipated loads to ensure the structure remains safe even under unusual conditions. Load capacity calculations often involve factors of safety exceeding 2.0, depending on the specific use and jurisdiction.

Regular Inspections and Maintenance

Regular inspections and maintenance are essential for preserving the safety and longevity of aluminum platform decks. Inspections should identify any deterioration, damage, or wear and tear. Maintenance procedures should address any identified issues promptly. These procedures may involve cleaning, repainting, or replacing components. Regular inspections are critical in identifying potential hazards early on and preventing accidents. A well-maintained deck reduces the risk of structural failure and enhances safety.

Summary of Safety Regulations and Standards

| Regulation | Description | Compliance Requirements | Penalties |

|---|---|---|---|

| Local Building Codes | Specific regulations for construction within a particular municipality. | Adherence to all local codes related to materials, design, and construction methods. | Varying fines and potential project suspension, depending on the severity of the violation. |

| OSHA Standards (if applicable) | Occupational Safety and Health Administration regulations for workplace safety. | Compliance with OSHA standards related to fall protection, access, and safety equipment, depending on the use. | Fines, penalties, and potential legal actions. |

| ASTM Standards (if applicable) | American Society for Testing and Materials standards for materials and construction. | Compliance with relevant ASTM standards for aluminum, fasteners, and structural components. | Varying fines and potential legal actions. |

| State/National Building Codes (if applicable) | State or national building codes covering general construction standards. | Adherence to state or national codes for construction materials, design, and structural integrity. | Varying fines and potential project suspension, depending on the jurisdiction and severity of the violation. |

Environmental Impact

Aluminum platform decks offer a compelling alternative for outdoor living spaces due to their durability and aesthetic appeal. However, understanding the environmental footprint of these structures is crucial for responsible design and construction. Careful consideration of material sourcing, disposal, and the overall lifecycle impact is essential for minimizing the environmental impact.

Aluminum, a lightweight and strong metal, presents a unique perspective on sustainability compared to other materials. Its recyclability and relatively low embodied energy make it a desirable option in environmentally conscious construction.

Material Sourcing and Disposal

The environmental impact of aluminum platform decks starts with the sourcing of the raw materials. Aluminum production, while highly energy-intensive, leverages recycled aluminum extensively. The use of recycled aluminum significantly reduces the energy needed compared to extracting aluminum from bauxite ore. Proper end-of-life planning for the deck is also important. Aluminum is easily recycled, minimizing waste and reducing the need for new material extraction.

Recyclability of Aluminum

Aluminum possesses exceptional recyclability, making it a highly sustainable material. The recycling process for aluminum requires significantly less energy than extracting new aluminum from its ore. Aluminum can be recycled indefinitely without losing its quality. This inherent recyclability directly contributes to a reduced carbon footprint and resource conservation. The recycling rate of aluminum varies geographically, but in many developed countries, it’s exceptionally high.

Environmental Footprint Comparison

Comparing the environmental impact of aluminum decks with other materials reveals compelling advantages. Wood, for example, while visually appealing, often requires significant land clearing and can have a higher carbon footprint, especially when considering the transportation of lumber over long distances. Concrete, while durable, has a high embodied energy due to the energy required in its production and transportation. Aluminum, with its high recyclability and relatively low embodied energy, demonstrates a favorable comparison.

Eco-Friendly Practices

Several eco-friendly practices can be incorporated into aluminum platform deck construction. Using recycled aluminum in the fabrication process is a primary example. Minimizing material waste during fabrication and construction through precise cutting and assembly is another crucial step. Using locally sourced aluminum components and employing sustainable transportation methods for materials reduces the overall environmental impact. Design choices that maximize natural light and ventilation, minimizing the need for artificial lighting and cooling, can also contribute to reduced energy consumption.

Sustainable Materials and Practices

- Recycled Aluminum: Utilizing recycled aluminum in the fabrication process significantly reduces the environmental impact of the deck by minimizing the energy required to produce new aluminum. It also conserves natural resources.

- Low-VOC Paints and Finishes: Using paints and finishes with low volatile organic compounds (VOCs) reduces air pollution during application and throughout the deck’s lifespan.

- Sustainable Lumber for Support Beams (if applicable): If using wood for support beams, choosing responsibly sourced wood from sustainably managed forests is crucial. Look for certifications like the Forest Stewardship Council (FSC) to ensure sustainable forestry practices.

- Energy-Efficient Lighting: Employing LED lighting for the deck can significantly reduce energy consumption compared to traditional incandescent or fluorescent lighting.

- Water-Wise Landscaping: If incorporating landscaping around the deck, select native plants and drought-resistant species to minimize water usage.

- Minimizing Material Waste: Implementing precise cutting and assembly techniques during fabrication reduces the amount of scrap material generated.

- Local Sourcing of Materials: Sourcing aluminum and other components locally reduces transportation emissions and supports local economies.

Conclusion

In conclusion, aluminum platform decks present a compelling combination of strength, durability, and aesthetic appeal. This guide has provided a comprehensive overview of their design, construction, maintenance, and environmental impact, offering a detailed understanding of the factors influencing the choice and application of these versatile structures. By considering the various aspects discussed, you can make an informed decision about whether an aluminum platform deck is the right fit for your needs.